Whenever air is required for combustion, fluidization, cooling systems, reaction, and other purposes fan, blowers and compressors are used as per required pressure.

Fan :

when air is required in less pressure and more volume than a fan is used. Generally, the fan creates pressure less than 3.45 Kpa g.There are mainly two types of fans :

(1)Forced draft fan

(2)Induced draft fan

(1)Forced draft fan: Almost every combustion chambers, preheated, boiler system for power generation and cooling systems inlet or suction side forced draft fan is used.

- forward curve blades are used in this type of fan which creates less pressure with a large volume flow rate of air.

(2)Induced draft fan: used in an exit air system or chimneys, product outlet this type of fan is used.

- Induced draft fan creates a vacuum at suction side and throws exhaust air into the atmosphere through Chimney. In this type of fan backward types of blades are used which creates more pressure and flow rate than forwarding type blades.

Blowers:

When air required pressure between 3.45 to 101.325 Kpa g then a blower is used. Generally, the creation of low vacuum blowers is used.

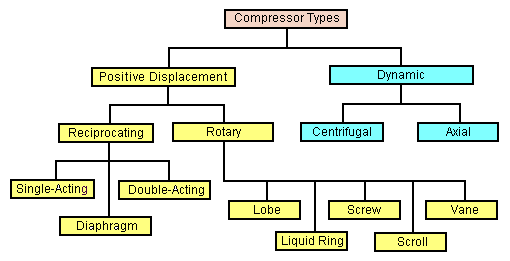

Compressors :

- More than 1 atm g or 101.325 Kpa g pressure is created by compressors. When required high pressure for reaction and for storing of gas compressors are used

- For example, in an ammonia plant, N2 and H2 react at high pressure (around 200atm) and high temperature (around 450° C) and also pressurized it to store in the vessel.

- The most common type used in industries is the reciprocating compressor. Which again classified into the single and double-acting compressor.

let's see this two one by one.

(1) single-acting compressor: In this type compressor takes suction through only one side and compresses by the piston. Forward movement of piston air is compressed and in backward no, any operation carried out. Fluctuation in pressurized air product in more of this type.

(2) Double acting compressor: In this type, the compressor takes suction through two sides. In forwarding and backward movement of the piston, compression action takes place. It creates less fluctuation in pressured air product than a single-acting compressor.