Pumps are uses in almost every industry to transfer water, chemicals, oil, petroleum, different types of food and pharmaceutical products, etc.

What is the pump?

A pump is a mechanical device used to transfer fluid from one to another place.How pump works?

The pump uses mechanical energy due to this pressure of fluid rises which is directly proportional to the velocity of the fluid. Because of high-velocity fluid can transfer to at high head.

Types of pumps?

Pumps are classified into two types:1) Dynamic pump

2) Positive displacement pump

Again these two are sub-classified into several types based on the type of fluid, position, and function of the pump.

1) Dynamic pump: These types of pumps are used for high flow rate and high head.

Types of the dynamic pump are as below:

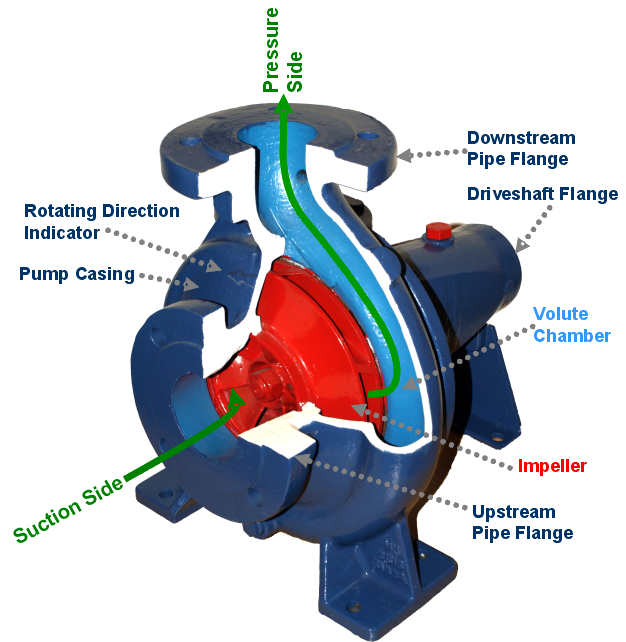

1. Centrifugal pump: Most common type of dynamic pump. uses rotational force which is created by the rotating impeller.

Fluid inlet to the impeller eye and rotational motion of impeller accelerates the fluid flow.

Based on impeller type centrifugal pumps are classified as:

1) Open impeller: impeller vanes are free on both sides.

2) semi-closed impeller: vane one side closed impeller

3) closed impeller: both sides of impeller vanes are closed.

Based on flow types centrifugal pumps are classified into three types.

1) axial flow pump: which directs the flow in an axial direction.

2) Radial flow pump: which directs the flow in the Radial direction.

3) mixed flow pump: characteristic of both axial and radial flow pump.

2. Speciality pumps: These types of pumps are made for special operations like the lifting of water from the source to the destination place.

Types of this pump are

1) jet pump: operates on the principle of jet and venturi effect which creates suction. Located above the liquid source.

Because of the venturi effect at the suction side pressure will be higher than atmospheric pressure which prevents cavitation.

2) Positive displacement pump: Generally this type of pump is used to create high pressure.

Types of positive displacement pumps are as below:

1) Rotary pump: Gives rotational motion to the fluid but fluid can move only in one direction.

Types of Rotary pumps are as below:

1. Gear pump: The gear pump transfers fluid utilizing gears. This gear can handle viscous fluid like oil.

This type of pump is used for lubrication purposes.

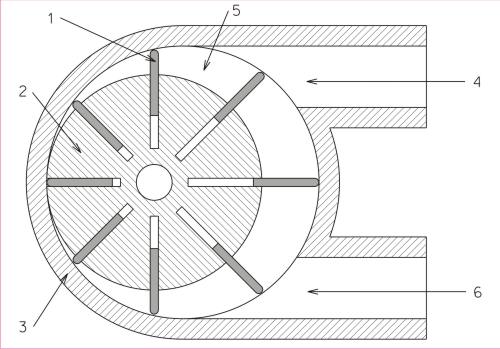

3. Vane pump: Vanes are mounted to a rotor. fluid kept between two vanes cavity, as the rotor rotates volume of vanes keeps on decreasing and create pressure on the fluid.

5. Screw pump: Screw rotates in the cylindrical casing. fluid kept between the screw and inner part of the casing.

As the screw rotates fluid moves in to forward direction. It has a variety of uses like fuel injection, transfer of fluid with solids particles.

2) Reciprocating pump: use for the creation of high pressure than rotary pumps.

Types of the reciprocating pump are as below:

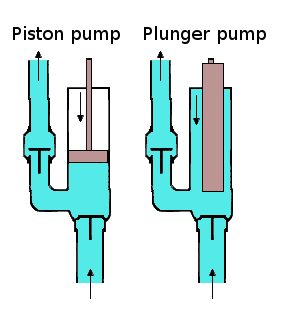

1. Piston pump: the seal is attached with a reciprocating piston to create pressure. Because the seal is sliding with the piston it can wear out.

2. Plunger pump: construction is the same as piston pump, but in place of the piston plunger is used and seal is fixed.

More pressure can create than the piston pump.

3.Diaphragm pump: A diaphragm pump is also known as a membrane pump.

Transfer a fluid by the reciprocating action of the diaphragm. It can evacuate air from the suction side, also known as a self-priming pump.

Uses for slurry liquid, abrasive and corrosive liquid.

Thank you bro its really helpful

ReplyDelete