The atmospheric Distillation Unit is one of the most important operations in petroleum refining. The atmospheric distillation unit provides raw materials for other operations which further improve the quality of petroleum products.

Working of Atmospheric Distillation Unit

After the desalting unit, Desalted crude is stored in storage. From storage, Crude oil is pumped to the atmospheric distillation unit.

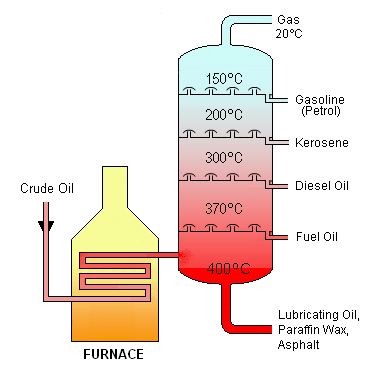

First of all crude oil is heated to convert low volatile products to the vapour phase. This operation is done in two stages:

- Heating by reflux of distillation unit

- Heating in a furnace

In heating by reflux of distillation unit, Heat is recovered from reflux streams of the atmospheric distillation unit. This operation helps in improving the overall economy of this operation. this operation heats crude oil to temperature to 300 °C.

After that, Crude oil is heated to 385 °C temperature with the help of pipe still heaters. This operation vaporizes most part of the crude oil stream.

The partially vaporized crude oil stream is then flashed into the distillation column. This flash zone is in between the enriching section and the stripping section. The vaporized part of crude oil is passed through the upper part of the distillation unit. Vapour-liquid equilibrium gets established at different trays. The column height is generally 50 m and contains about 30-50 valve trays.

Steam injected from the bottom of the distillation column. Steam provides heating liquid coming down the column and also it strips out a light component from crude oil. As stripping takes place in the lower part of the distillation column, This part is also called the stripping section.

There is no reboiler attached with crude distillation unit as attached with normal distillation carried out in other industries. Steam is injected as an alternative to reboiler. This steam does work of reboiler.

Now vapours generated establishes equilibrium with liquid coming down the column. The hot vapours from the flash zone is in contacts with liquid coming down. This liquid comes from the reflux stream. This reflux stream is pump around the reflux stream which is withdrawn from several trays and cooled by a feed crude oil stream.

Vapours reaching the top is condensed in a condenser. Cooling water is used to condense vapours coming to the top. A condensed stream contains lights that end with condensed light naphtha.

Also, Some part of the condensed stream is added back to the column as external reflux.

Different component stream is taken out from column and stripped out with the help of steam in the stripper. Different components come out from different tray draw according to their temperature on the tray.

Products that come out from the atmospheric distillation unit are petroleum gases, light and heavy naphtha, kerosene, light and heavy gas oil and atmospheric residue from the bottom of the column.