The most basic equipment a chemical engineer must know is a Centrifugal Pump. There are plenty of centrifugal pumps you will find in chemical and related industries. So being a chemical engineer it is required to know the centrifugal pump very well.

Learning about centrifugal pumps will not only help in your interview but you will also greatly benefit in your professional life if you want to work in the chemical industry.

So to make you aware of the most important concepts related to centrifugal pumps, I have written this complete guide of centrifugal pumps.

There are two major types of pumps

Other important things not a part of the pump but used with the pump are

There are three major types of impellers available for different liquids it is used to handle.

Now three different types of casing are commonly used in the pump.

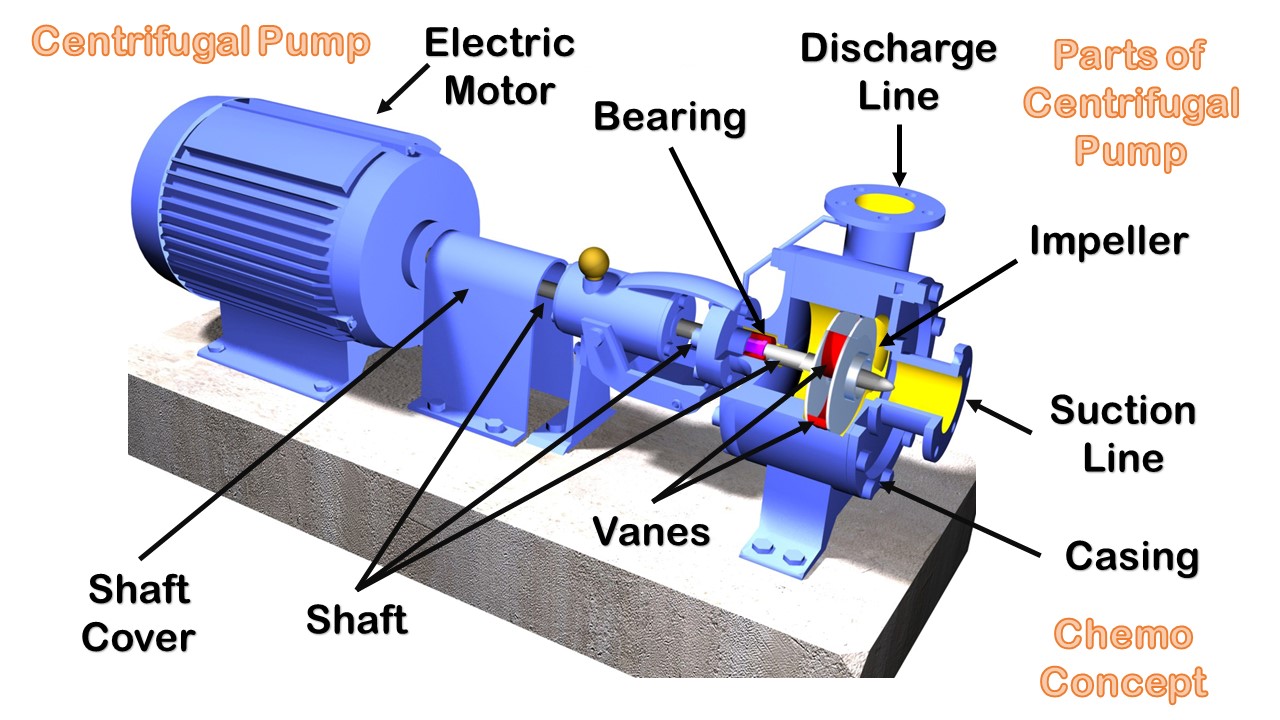

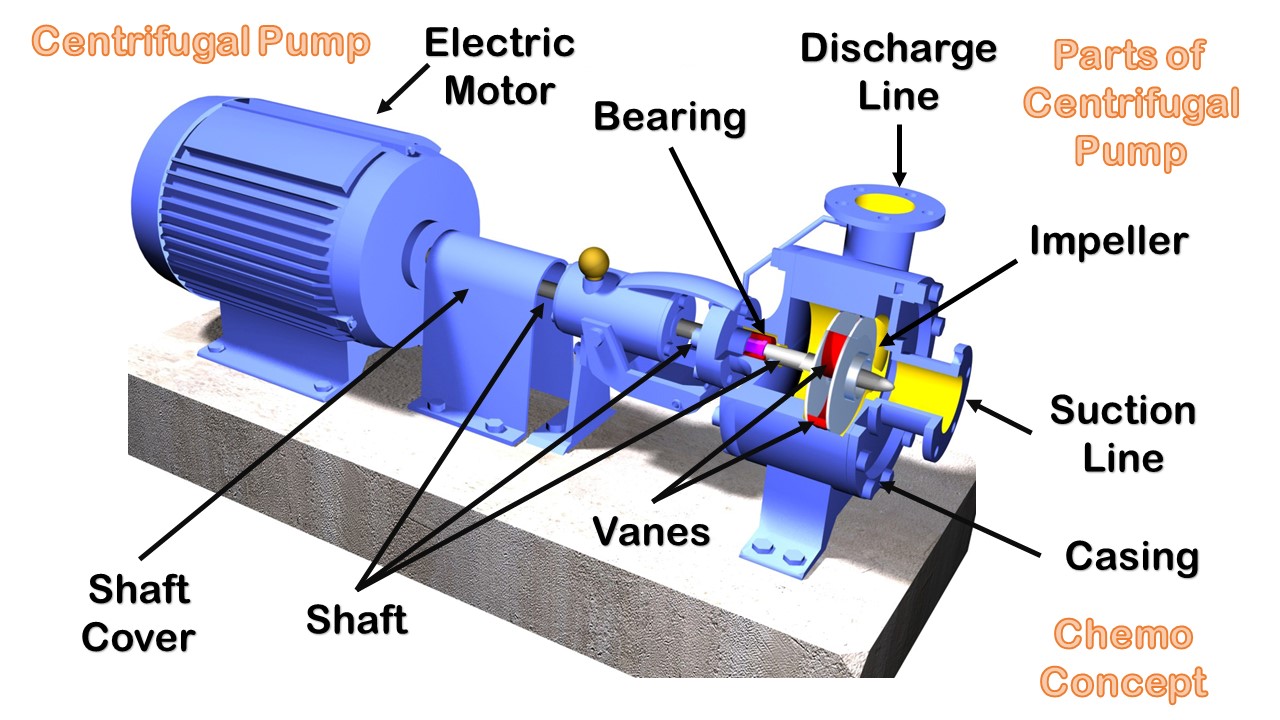

So here is an image of parts of pumps which is

So here you can see the damage caused by cavitation. Now, You can understand the level of damage cavitation can cause. So, there are many prevention techniques for cavitation. The first and the most important technique is to keeping NPSH(Available) should be higher than NPSH(Required).

Now let me explain what is NPSH.

There are two types of NPSH to be required to check the condition of cavitation.

The formula of NPSH(Available) is:

`NPSH_{Available}` = `{P/(\rhog)}\ -\ h_{fs}\ -\ {P_v/(\rhog)} \pm H`

Here,

P = Absolute Pressure at Suction Side

`h_fs` = Head Loss due to Friction on Suction Side

`P_v` = Vapor Pressure of Liquid at Pump's Operating Temperature

H = Difference in height of Pump and Liquid Level in Sump

`\rho` = Density of Liquid

g = Gravitational Acceleration

Now, Here value of H depends on the location of the sump. If the sump is located above the pump, The value of H will be positive and If the sump is located below the pump, its value will be negative. The sump above the level of the pump will help liquid flowing to the pump so it is positive.

Now, From the above formula, We can calculate NPSH(Available) value for the pump, and NPSH(Required) value should be provided by the pump manufacturer. This NPSH(Required) value is dependent on the type of impeller, speed of rotation, and other parts of the pump. So, as we have both NPSH(Required and NPSH(Available), We can check conditions for cavitation.

Now, From the initial check, we got to know that the value of NPSH(Required) is more than NPSH(Available). There are several things you can do to increase the value of NPSH(Available) or to reduce the value of NPSH(Required).

There is a simple solution to prevent air binding - Priming. In priming, We initially add liquid to the pump from a small opening on the pump and fill until pumps get full of liquid. The small vent of the pump casing is opened until the pump is primed and when liquid starts to come out from that vent, Priming can be stopped. Now, if we start the pump, the pump can create enough suction so it can easily draw liquid to it.

Another solution is to provide a check (non-return) valve to the suction side. This valve automatically prevents liquid from falling down to the sump from the pump when the pump is stopped which removes the hassle of priming the pump in every startup. Now, Another small pump to draw liquid to the pump at the beginning can also be a choice.

Characteristics curves that are mostly used in the industry contain flow rate on the horizontal axis and other parameters such as head developed, power required, NPSH(Required), and Efficiency on the vertical axis.

The image below is a Characteristics curve of a pump:

There are major three curves in the above

Learning about centrifugal pumps will not only help in your interview but you will also greatly benefit in your professional life if you want to work in the chemical industry.

So to make you aware of the most important concepts related to centrifugal pumps, I have written this complete guide of centrifugal pumps.

Before getting into centrifugal pumps, First of all, let's start by learning what is the pump.

What is a pump?

A pump is a mechanical device that is used to transfer liquid from one place to another place by converting mechanical energy to the pressure energy of the liquid. A pump is commonly used to transfer liquids(e.g. Water), solutions (e.g. sodium hydroxide aqueous solution), and slurries (e.g. crude oil).

- Dynamic Pumps

- Positive Displacement Pumps

- Rotary Pumps

- Gear Pumps

- Lobe Pumps

- Vane Pumps

- Screw Pumps

- Peristaltic Pumps

- Reciprocating Pumps

- Piston Pumps

- Plunger Pumps

- Diaphragm Pumps

Dynamic pumps are sub-classified into other two types of pumps:

Centrifugal pumps are widely used in chemical and other related industries due to their simple design, low maintenance requirement, low cost, and flexible operation. So learning about centrifugal pumps becomes essential for every chemical engineer. Now let's start learning about centrifugal pumps

- Centrifugal Pumps

- Axial Pumps

Centrifugal pumps are widely used in chemical and other related industries due to their simple design, low maintenance requirement, low cost, and flexible operation. So learning about centrifugal pumps becomes essential for every chemical engineer. Now let's start learning about centrifugal pumps

What is a centrifugal pump?

A Centrifugal pump is a mechanical device that pumps liquids by imparting mechanical energy to liquid and increasing its kinetic energy which is further converted into pressure energy to transfer it. Centrifugal pumps are used to pump a high amount of liquids to moderately high heads.Principle of Working of a Centrifugal Pump

Pumps works on principles of centrifugal force also called centrifugal action. The rotating impeller imparts energy to the liquid which is used to transfer it.Working of a Centrifugal Pump

The working of the centrifugal pump can be understood in several steps.- First of liquid is drawn from the sump to the pump through the suction line. The suction line contains a flow regulation valve and also sometimes contains a check valve whenever liquid is drawn from the sump below the level of the pump. This check valve closes down when the pump is stopped which prevents liquid from falling down to the sump from the pump. This removes manual priming. Priming means filling liquid in the pump before starting out. Priming is discussed later in the article.

- Now liquid coming in from the suction line comes in contact with the impeller. The rotating impeller drags the liquid with it and transfers some of its kinetic energy to the liquid.

- Now liquid having high velocity comes in the contact with a casing which due to its gradual cross-sectional area change, converts liquid's kinetic energy into pressure energy.

- Now liquid having high-pressure energy leaves the pump.

Parts of a Centrifugal Pump

There are major two parts of a centrifugal pump- Motor (or Turbine)

- Shaft

- Mechanical Seal (or Stuffing Box)

- Impeller

- Casing

Other important things not a part of the pump but used with the pump are

- Sump and Suction Pipe with Foot Valve

- Discharge Pipe and Discharge Valve

Motor (or Turbine)

Motors or turbines are common drivers of centrifugal pumps. Motor by using electricity drives the shaft. Turbines are also sometimes used to drive the shaft of the pump.Shaft and Bearing

The shaft connects the pump with the motor. The kinetic energy generated from the electric energy in the motor is transferred to the pump with the shaft. The shaft is supported on bearing on both sides.Mechanical Seals (or Stuffing Box)

Mechanical seals and stuffing box is used to prevent leakage from the pump where the shaft enters the pump. The liquid may come out from where the shaft is entering into the pump so the use of mechanical seals or a stuffing box (whenever required) is a must. A stuffing box is commonly used for common liquids. For corrosive or high-pressure liquids mechanical seal is used because it requires low maintenance cost.Impeller

The impeller is one of the most important parts of a centrifugal pump and is often called the heart of a centrifugal pump. The impeller is a rotor containing curved blades also called vanes. The impeller is joined with the shaft which is connected with the motor. Energy is transferred to the impeller by rotation with the help of the shaft. The blades are manufactured as smooth as possible to reduce frictional losses.There are three major types of impellers available for different liquids it is used to handle.

- Open impeller: Open impeller contains a bunch of blades joined by the central ring. this type of impeller is best suited for slurries containing suspended solids. This type of impeller is the least efficient type of impeller because of poor contact.

- Semi-open impeller: Semi-open impeller contains blades joined by the central ring also supported by one disk. The disk is called the base plate because it supports the impeller blades. This type of impeller is best suited for liquids containing a low amount of suspended solids.

- Closed impeller: Closed impeller contains blades joined by the central ring and two disks. One blade is called a base blade, another is called the crown blade. This type of impeller should be used for clear liquids having no suspended solids. This type of impeller is the most efficient type of impeller because it provides the best impeller liquid interaction.

Casing

The outer-most cover of the pump is called its casing. The casing is one of the most visible parts of the pump. Casing not only protects liquid and components of centrifugal pumps from the outside atmosphere but also converts the kinetic energy of liquid to pressure energy. The casing is fabricated in a way that it works as an airtight chamber.Now three different types of casing are commonly used in the pump.

- Volute Type Casing: This type of casing forms a volute shape of increasing cross-sectional area. In this type of casing, Liquid flowing outward from the impeller comes in contact with the casing. Casing having increasing cross-sectional area, Velocity of the liquid decreases and pressure of the liquid increases, As one of the energy decreases, other increases (Bernoulli Theorem). So we can say that volute converts the kinetic energy of liquids to its pressure energy. One of the drawbacks of using this type of volute style design is that due to change in the direction of liquid flow, there are chances of eddy formation. This eddy formation results in considerable energy loss.

- Vortex Chamber Type Casing: This type of casing is developed to overcome the energy loss taking place in the volute type of casing. Vortex chamber type casing contains a circular chamber between casing and impeller blades. This extra space provides enough space for directional velocity change which reduces the number of eddies formed. So, due to low amount of eddied formed these design improves the overall energy economy.

- Diffuser Type Casing: This type of casing contains guided vanes which are also known as diffusers. These are stator blades (guide vanes) placed at the ring placed after the impeller blades. Liquid passes through the impeller which increases the kinetic energy of liquids. Guided vanes or stator blades help liquid changing the direction of the liquid.

Problems Associated with Centrifugal Pump

Because of the wide application of pumps in chemical industries, it is important to learn about some important problems related to centrifugal pumps. There are major two problems related to the centrifugal pump which are commonly encountered in daily operation.- Cavitation

- Air binding

Cavitation in Centrifugal Pump

When the pump is drawing water from the sump which is below the level of the pump, the pump creates a negative pressure at the suction side which draws the liquid to it. If this negative pressure is more than the vapor pressure of the liquid. Liquid starts to boil inside the pump and bubble formation takes place of vapors generated. Now, these bubbles may collapse inside the pump and can cause harm to the impeller and another part of the pump.So here is an image of parts of pumps which is

So here you can see the damage caused by cavitation. Now, You can understand the level of damage cavitation can cause. So, there are many prevention techniques for cavitation. The first and the most important technique is to keeping NPSH(Available) should be higher than NPSH(Required).

Now let me explain what is NPSH.

Net Positive Suction Head (NPSH)

The net positive suction head is a quantity that is calculated to find out if cavitation is going to happen in the pump at a certain arrangement. The NPSH plays an important role in the placement of pumps in plants.There are two types of NPSH to be required to check the condition of cavitation.

- NPSH(Available) - To be calculated on the field condition

- NPSH(Required) - To be provided by the pump manufacturer

The formula of NPSH(Available) is:

`NPSH_{Available}` = `{P/(\rhog)}\ -\ h_{fs}\ -\ {P_v/(\rhog)} \pm H`

Here,

P = Absolute Pressure at Suction Side

`h_fs` = Head Loss due to Friction on Suction Side

`P_v` = Vapor Pressure of Liquid at Pump's Operating Temperature

H = Difference in height of Pump and Liquid Level in Sump

`\rho` = Density of Liquid

g = Gravitational Acceleration

Now, Here value of H depends on the location of the sump. If the sump is located above the pump, The value of H will be positive and If the sump is located below the pump, its value will be negative. The sump above the level of the pump will help liquid flowing to the pump so it is positive.

Now, From the above formula, We can calculate NPSH(Available) value for the pump, and NPSH(Required) value should be provided by the pump manufacturer. This NPSH(Required) value is dependent on the type of impeller, speed of rotation, and other parts of the pump. So, as we have both NPSH(Required and NPSH(Available), We can check conditions for cavitation.

To avoid cavitation in the pump, the value of NPSH(Available) should be higher than the value of NPSH(Required).

Now, From the initial check, we got to know that the value of NPSH(Required) is more than NPSH(Available). There are several things you can do to increase the value of NPSH(Available) or to reduce the value of NPSH(Required).

- Change the location of the pump: By shifting the pump to the location where the difference in height of the pump and sump is not much, We can increase the value of NPSH(Available).

- By providing cooling to the suction side to reduce the vapor pressure of the liquid, Which leads to increasing NPSH(Available).

- By reducing the operating speed of the pump, which eventually reduces the NPSH(Required).

Air Binding

Centrifugal pumps are designed to transfer liquids. But on the startup of the pump, the pump might not have contained liquid and contains air. This air just circulates when the pump starts and doesn't provide enough suction on a suction pipe which can suck liquid to the pump. So, The pump keeps rotating its impeller without really drawing liquid in it. This phenomenon is called air binding.There is a simple solution to prevent air binding - Priming. In priming, We initially add liquid to the pump from a small opening on the pump and fill until pumps get full of liquid. The small vent of the pump casing is opened until the pump is primed and when liquid starts to come out from that vent, Priming can be stopped. Now, if we start the pump, the pump can create enough suction so it can easily draw liquid to it.

Another solution is to provide a check (non-return) valve to the suction side. This valve automatically prevents liquid from falling down to the sump from the pump when the pump is stopped which removes the hassle of priming the pump in every startup. Now, Another small pump to draw liquid to the pump at the beginning can also be a choice.

Losses in a Centrifugal Pump

There are major three types of losses that can occur in a centrifugal pump.- Energy Loss: Energy losses that happen in the pump. Such losses are from friction caused by different moving parts of pumps and eddies caused due to the flow of liquid.

- Material Loss: Materials losses due to leakages are loss of material caused by the small opening in the pump which is not completely sealed.

Characteristics Curves of The Centrifugal Pump

The characteristics curves of the pump represent different parameters such as flow rate, head developed, the power required, NPSH(Required), and their relations. These curves are most helpful when predicting the performance of the pump at different process conditions. So from that, these curves are also called performance curves.Characteristics curves that are mostly used in the industry contain flow rate on the horizontal axis and other parameters such as head developed, power required, NPSH(Required), and Efficiency on the vertical axis.

The image below is a Characteristics curve of a pump:

There are major three curves in the above

- H vs Q Curve: This curve shows the relation between flow rate and head developed by the pump. The pump starts at a flow rate is equal to zero which means when the delivery valve is completely closed. In this situation, the pump produces maximum head. As the flow rate increases, the head drops. So there is the decreasing curve of head and flow rate.

- P vs Q Curve: This curve shows the relation between flow rate and power required by the pump. As the flow rate increases, the power required by the pump also increases because more amount of liquid needs higher power for transferring. So, there is the increasing curve of power vs flow rate.

- `\eta` vs Q Curve: This curve shows the relationship between the efficiency of the pump and the flow rate of the pump. At first, As the flow rate increases, Efficiency also increases. But after a peak, it starts to decline. The point having the highest efficiency is called Maximum Efficiency Point. The pump is ideally operated near the maximum efficiency point.

- Also, some curve contains NPSH(Required) vs flow rate. There is a slight increase in NPSH(Required) as the flow rate increases.

Centrifugal Pump Startup Procedure

- Close the valve on the delivery side of the pump

- First of all, prime the pump if the pump requires the priming

- Open the valve on the suction side of the pump

- Start the motor of the pump

- As Pumps starts check the pressure of the delivery side.

- If you see the pressure in the delivery side is enough open the delivery valve slowly.

- If you feel like there is some problem, Just close the recirculation line and close the delivery line.

- Check if the problem continues or is resolved. If the same problem arises in the recirculation, There may be a problem in the pump. If not, there may be a problem with the delivery pipe of the pump.

- If the pump is cavitating, it will cause a strange sound of the collapsing bubbles. So when encountered stop the pump and start with the pump on standby.

Advantages of Centrifugal Pump

- The high amount of liquid can be transported to moderately high heads.

- Flexible Operation (Can work on any speed according to motor coupled)

- Lower initial investment and simple design and construction

- A lower amount of maintenance is required

- Can be used for a wide variety of liquids also for liquids carrying suspended solids

- Small size so requires small space for installation

- Doesn't get damaged when the delivery valve is closed for some time as other pumps get.

- By sealing it with the motor, it can also be used as a submersible pump that draws liquid from the tank.

Disadvantages of Centrifugal Pump

- Requires priming on startup

- Can not be used where a high head of liquids are required

- Not very efficient in transferring high viscosity liquids

- Usually operates at lower efficiencies